Overview

PET double sided tape is known for its transparency and strong adhesion. It is widely used in various industries due to its excellent performance and aesthetic appeal.

Transparency: PET double sided tape is transparent, making it ideal for applications where appearance matters, such as display racks, posters, and decorative items.

Temperature Resistance: Can withstand temperatures from -40°C to 120°C, suitable for environments with large temperature fluctuations, such as automotive and industrial applications.

High Adhesion: Strong bonding capability on various surfaces, including slightly uneven or rough materials, forming a durable bond.

Chemical and Water Resistant: Resists chemical corrosion and offers good waterproof performance, suitable for humid environments or areas exposed to chemicals.

Electronics: Used for fixing electronic components and bonding circuit boards.

Automotive: Applied for securing car parts like tail lights and bumpers.

Construction: For attaching decorative materials such as mirrors and tiles.

Office & School: Ideal for mounting posters and photos.

Crafts & Hobbies: Popular among DIY enthusiasts and craft makers.

Professional Manufacturing: NB Technology Co., Ltd. is professional double sided adhesive tape manufacturers with advanced equipment and rich experience, ensuring product quality and stable supply.

Customization: Custom services available for size, shape, color, and adhesive strength according to customer needs.

Quality Assurance: Strict quality control system with certifications and testing reports provided to guarantee reliability.

Advantages

| Item description: | Double faced adhesive tape |

| Brand name: | NB |

| Prime material: | PET |

| Feature: | ● Good dimensional stability, thermal stability, chemical stability, good initial adhesion and adhesion retention;● Easy die-cutting, good adhesion to plastics, rubbers and nameplates. |

| Usage: | ● It can be used for automobile decorative strip, sealing strip, automobile air conditioner, nameplate, audio, shockproof and heat preservation;● Elevator stainless steel door plate fixing, building decoration parts bonding;● All kinds of household appliances nameplate, refrigerator evaporator and other electrical parts fixed, membrane switch;It can also be used for sound insulation, heat preservation, and bonding of daily necessities;Cell phone die-cutting accessories, cell phone used in the LCD backing, the main screen lens double-sided adhesive, the main screen decorative parts backing, chassis backing, lens backing, camera lens backing, camera decorative parts backing, camera foam, camera dust pads. |

| Heat resistance: | Used in constant temperature |

| Adhesive type: | Oil-based |

| Thickness of substrate: | 140±5 |

| Peel force (g/25mm): | ≥23 |

| Specification: | Can be totally customized for you |

| Color: | Transparent or semi transparent |

| MOQ: | About 600Kgs |

| Delivery time: | Within 15 days through peak and off season for you |

| Sample: | Free sample is always available for you to test our quality |

| Packing: | Carton packaging |

| Payment method: | T/T / L/C /Cash or negotiable |

| HS Code: | 3919909090 |

Production Process

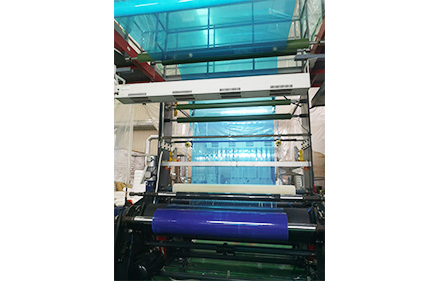

FILM BLOWING

In the film blowing process, we use advanced production equipment and imported raw materials to strictly control the protective film quality from the source.

PRINTING

In the printing process, we use environmentally friendly painting by introducing advanced production techniques and equipment, it is now possible to print four patterns and colors in one film.

COATING

We use imported glue and strictly control the quality of finished films, to achieve moderate viscosity and ensure no residue after the removal, also provide you with a good experience of use.

CUTTING

There are seven machines in our cutting workshop, each and every one of them can be adjusted to cut different lengths of protective films to meet your needs.

PACKAGING

We use standard seaworthy packaging to pack the films for you to avoid any possible damage during the transit and storage, packing of customization is also available for you.

Film Blowing

In the film blowing process, we always insist on using brand new and environmental-friendly LLDPE raw materials to ensure the stable quality from the very beginning and we absolutely say “No” to any recycled raw materials.

Film Casting

In the film casting process, our experienced team has every input data precisely set and checked to ensure the good and stable output of our final stretch wrap films. Because we always pay particular attention to every single detail during the whole proce

Film Testing

Our stretch wrap films feature strong toughness and tear resistance, and can not be penetrated easily by the nib under the intense stretch. They also feature strong tensile strength which enables you to wrap three more pallets with the same meters.

Packaging

We use standard seaworthy packaging to pack the stretch wrap films for you to avoid any possible damage during the transit and storage, you can also enjoy customized packaging from our side.

FILM BLOWING

In the film blowing process, we use advanced production equipment and imported raw materials to strictly control the protective film quality from the source.

Container Stuffing

Protective Film for Deep Drawing

Transportation of Protective Film for Deep Drawin

Packing of Protective Film for Deep Drawin

Loading of Protective Film for Deep Drawin

Navigation

+86 158 1691 5404

+86 757 8271 3937

+86 757 8271 3937

No. 10 Industry Huacongsiyue Village, Shishan Town, Nanhai District, Foshan, Guangdong Province, China