Nov. 10, 2025

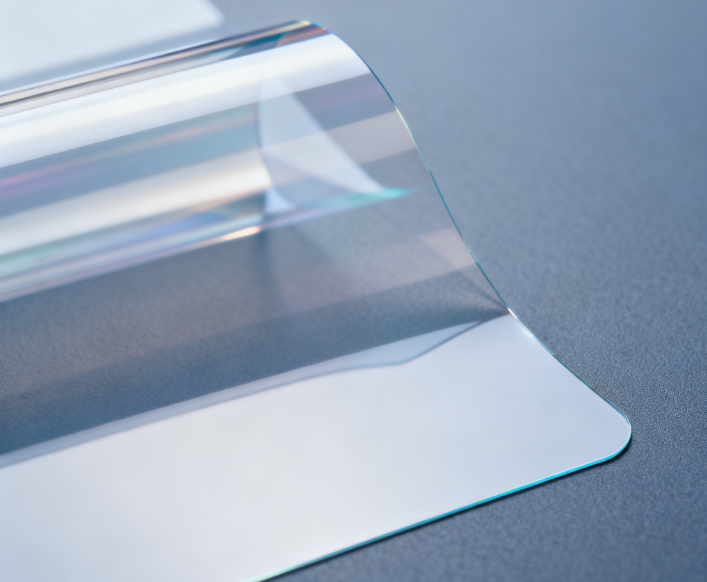

As laser processing becomes increasingly central to modern manufacturing—spanning industries from automotive and electronics to medical devices and precision machinery—the importance of high-quality laser protection films has never been higher. These films safeguard delicate surfaces during laser marking, cutting, welding, and engraving, helping factories reduce rework, minimize scrap, and improve overall productivity.

However, not all suppliers are created equal. Selecting the right laser protection film partner requires careful evaluation across multiple criteria to ensure quality, consistency, and long-term reliability. This guide outlines the key checklist items manufacturers should consider when choosing a laser protection film supplier.

The foundation of a reliable laser protection film supplier lies in the quality of the materials they provide. Critical factors include:

The film must withstand the intensity of laser energy used in your operations without melting, discoloring, or delaminating.

High-performance films are typically designed for specific wavelength ranges and laser types (fiber, CO₂, YAG), so ensure compatibility.

Adhesive strength should be sufficient to prevent lifting during handling or laser operations.

Equally important is residue-free removal to protect the substrate surface and avoid secondary cleaning processes.

Tear resistance, puncture resistance, and abrasion resistance are essential, especially for parts handled by robots, conveyor belts, or manual operators.

Multi-layer polymeric structures are often used to provide balanced mechanical and thermal protection.

A trustworthy supplier should comply with relevant international and industry standards:

ISO 9001 Quality Management: Ensures consistent product quality and process control.

ISO 14001 Environmental Management: Demonstrates commitment to sustainable production practices.

RoHS and REACH Compliance: Critical for electronics and consumer products to meet regulatory requirements.

FDA or EU Food Contact Compliance: Necessary if films are used on surfaces for food processing or medical devices.

Valid certifications indicate that the supplier adheres to strict quality and safety protocols, reducing risk for manufacturers.

Every manufacturing line has unique requirements. Reliable suppliers should offer flexible customization options:

Film thickness: Adjusted for laser power, substrate sensitivity, or protective duration.

Adhesive strength: Tuned to different materials (metal, plastic, glass) and surface treatments.

Color and transparency: Ensures visibility of markings while maintaining protection.

Width, length, and roll formats: Compatible with automated feeders, manual application, or large-scale production lines.

Suppliers capable of customization can optimize protection without compromising efficiency.

Consistent supply is critical for high-volume manufacturing operations. Key considerations include:

Manufacturing scale: Can the supplier handle large orders while maintaining quality?

Lead times: Are delivery schedules consistent with production planning?

Inventory management: Does the supplier maintain safety stock to avoid line downtime?

Global logistics support: Especially important for multinational factories or multiple production sites.

A reliable supplier ensures uninterrupted production and prevents costly delays or emergency sourcing.

Laser protection films are not just off-the-shelf products; optimal performance requires correct application and handling. Evaluate supplier support in:

Application guidance: Training on surface preparation, film application, and removal techniques.

Process integration: Advice on integrating films with laser power settings, marking speeds, and conveyor systems.

Problem-solving: Rapid response for troubleshooting surface defects, adhesion issues, or film compatibility problems.

Documentation: Clear technical datasheets, safety information, and compliance certificates.

A supplier offering strong technical support becomes a partner in efficiency, not just a product vendor.

Evaluating a supplier’s experience and reputation is crucial:

Industry experience: Years of working with laser processes and high-volume manufacturers.

Case studies: Evidence of cost savings, defect reduction, and improved throughput.

Customer testimonials: Real-world performance feedback from companies in similar sectors.

Innovation history: Ability to adapt and develop next-generation films for evolving laser technologies.

Suppliers with proven track records reduce the risk of inconsistent product performance.

Sustainability is becoming a key factor in supplier selection. Consider:

Low-VOC or solvent-free formulations: Minimize environmental impact and comply with local regulations.

Recyclable or biodegradable film options: Reduce waste in production facilities.

Energy-efficient production processes: Demonstrates commitment to corporate sustainability goals.

Manufacturers increasingly prioritize partners whose products align with their green manufacturing initiatives.

While price is a factor, total value is more important than unit cost:

Reduced rework and scrap: High-performance films lower overall production costs.

Extended line uptime: Reliable supply and quality reduce downtime.

Compatibility with automation: Efficient film formats reduce labor costs.

Long-term savings: Avoiding surface defects and rework offsets initial purchase price.

Selecting based solely on low price often leads to higher operational costs.

When evaluating potential suppliers, manufacturers should ensure the following:

Material quality: Thermal, laser, chemical, and mechanical protection.

Certifications: ISO, RoHS, REACH, FDA compliance if applicable.

Customization options: Thickness, adhesive strength, color, roll dimensions.

Supply reliability: Production capacity, lead times, inventory management.

Technical support: Application guidance, troubleshooting, process integration.

Proven track record: Case studies, references, industry experience.

Sustainability practices: Low VOC, recyclable materials, energy-efficient production.

Total cost value: Consider savings from defect reduction, throughput improvements, and labor efficiency.

Selecting a reliable laser protection film supplier is critical for modern manufacturing facilities that rely on laser marking, cutting, and welding. By carefully evaluating material quality, certifications, customization capabilities, supply reliability, technical support, track record, sustainability, and total cost value, manufacturers can minimize surface defects, reduce rework, and optimize production efficiency.

Partnering with a trusted supplier such as NB Technology ensures consistent high-performance films, technical guidance, and measurable cost savings, helping factories maintain both quality and competitiveness in increasingly demanding industrial environments.

Navigation

+86 158 1691 5404

+86 757 8271 3937

+86 757 8271 3937

No. 10 Industry Huacongsiyue Village, Shishan Town, Nanhai District, Foshan, Guangdong Province, China