Overview

PET high-temperature resistant protective films are mainly used for the protection of aluminium substrate oxidation process, soldering tin for electronic circuit board, various metal sheets surface and aluminium profiles during the high-temperature spraying. Our heat resistant PET protective films is mainly made of a particular formulation PET coated with special silica gel, which makes it easy to paste and remove from the surface of the object, That is to say, it has a very good performance in sticking and peeling. What is more, they are able to withstand high temperature of 90-230℃. That is why these heat resistant protective films are beneficial for your products.

Advantages

1. Ability to withstand high temperature of 90-230ºC. Our high temperature film offers excellent heat resistance, ensuring durability even in extreme temperature conditions.

2. Resistance to solvent, acid, and alkali corrosion. Our heat resistant film provides reliable protection against various chemicals, ensuring the integrity of your surfaces.

3. Good adhesion performance for all kinds of non-polar material surface. Our heat resistant PET film exhibits superior adhesion properties, making it suitable for a wide range of surfaces.

4. Temperature-resistance can be flexibly adjusted according to your requirements. Our high temperature film can be customized to meet specific temperature resistance needs, providing flexibility and versatility.

5. Very easy to apply and peel off without leaving any glue on the surface. Our heat resistant film ensures hassle-free application and removal, leaving surfaces clean and residue-free.

6. Our heat resistant PET film has ISO9001: 2008 Quality Management System Certification, ISO 14001: 2004 Environmental Certification.

Specifications

| Item description: | High-temperature resistant PET protective films, PET Protective Film |

| Brand name: | NB |

| Prime material: | Polyethylene Terephthalate (PET) |

| Functional Layers: | Two-Layer Technology |

| Heat-resistance level: | Flexibly adjusted according to your requirements |

| Peeling strength: | 100~140g/cm (Can be customized according to the surface) |

| Size: | (100-1000) mm |

| Film blowing: | Raw material (self-viscosity) is turned into a film in just one step |

| Cutting and slitting: | As per your requirement |

| Color: | Various colors for you to choose from |

| MOQ: | About 600Kgs |

| Delivery time: | Within 15 days through peak and off-season for you |

| Sample: | Free sample is always available for you to test our quality |

| Packing: | These protective films are packed in cartons or pallets if LCL |

| Payment method: | T/T / L/C /Cash or negotiable |

| HS Code: | 3919909090 for the type showing above |

| Customized service: | We can accurately customize the most suitable viscosity and heat-resistant level for you according to the surface smoothness as well as the production environment of your product. Contact us to get the most competitive quotation today! |

Production Process

FILM BLOWING

In the film blowing process, we use advanced production equipment and imported raw materials to strictly control the protective film quality from the source.

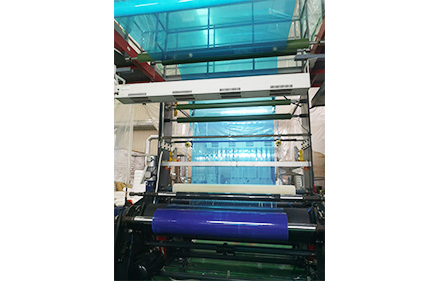

MULTIFUNCTIONAL FILM MAKING MACHINE

We always keep investing in the most advanced machine to produce premium protective films for our customers, such as this multifunctional electronic protective film making machine that features all-in-one production process like coating, drying and final rolling.

COATING

In the coating process for electronic protective films, our production team strictly has the glue formula and coating machine data checked and regulated during the whole process to ensure the stable viscosity of our films.

FINAL ROLLING

In the final rolling process, our state-of-the-of rolling machine can precisely and accurately roll the finished electronic protective films to the exact sizes we need for our customers.

PACKAGING

We use standard seaworthy packaging to pack the films for you to avoid any possible damage during the transit and storage, packing of customization is also available for you.

Container Stuffing

Protective Film for Deep Drawing

Transportation of Protective Film for Deep Drawin

Packing of Protective Film for Deep Drawin

Loading of Protective Film for Deep Drawin

Why Choose Us

More than one good reason for why you choose our heat resistant PET protective films, you will be benefited from our following advantages:

1. Fast lead time: within 15 days in both peak and off-season.

2. Strong heat resistant PET protective films production capacity: more than 20,000 tons of protection films per year.

3. Quality assurance: ISO9001: 2008 Quality Management System Certification.

4. Competitive heat resistant PET protective films pricing: we provide you with the most competitive direct factory pricing.

5. OEM & ODM services: we have a professional engineer team to serve you with OEM and ODM.

6. Heat resistant PET protective films free sample available: you can get our free protective film samples for quality testing.

7. Heat resistant PET protective films money-back guarantee: if you receive any defective protection films from our side, we will take full responsibility and help you sort out the issues without causing you any extra troubles or costs.

Navigation

+86 158 1691 5404

+86 757 8271 3937

+86 757 8271 3937

No. 10 Industry Huacongsiyue Village, Shishan Town, Nanhai District, Foshan, Guangdong Province, China