Overview

Double Sided Teflon Tape, typically composed of a Teflon-based substrate and strong adhesive on both sides. Teflon features excellent heat resistance, can normally be used in high temperature environments without deformation or loss of adhesion; it is chemically stable, resistant to corrosion and wear, capable of maintaining performance stability for a long time; it also has good non-stick properties, making it easy to apply and remove.

Industrial Manufacturing: In the electronics industry, it is used for fixing electronic components, sticking circuit boards, etc., such as bonding small electronic components to circuit boards or fixing displays, etc.; in automobile manufacturing, it can be used for sticking interior parts like dashboards, seat decorations, etc.; in mechanical processing, it is used for fixing workpieces and protective pads.

Construction & Decoration: Used for sticking decorative materials such as tiles and wooden floors, especially in positions requiring temporary fixation or with high surface requirements; in door and window installation, it can serve as sealing and fixing material to prevent air and water leakage, ensuring secure installation.

Daily Office & Life: In office settings, it can be used for binding documents, fixing office equipment, etc.; in family life, it's suitable for sticking photos, decorative paintings, and simple repair and fixation of household items.

Stable High-Temperature Performance: Maintains good adhesion over a wide temperature range without falling off or failing due to high temperatures, ensuring reliability in various environments.

Chemical Corrosion Resistance: Exhibits good tolerance to most chemicals, not easily corroded, prolonging product lifespan and reducing replacement frequency and maintenance costs.

Non-Stick and Easy to Clean: The attached object can be easily removed without leaving residual adhesive on the surface, keeping the surface clean and intact, facilitating subsequent cleaning and maintenance.

Good Insulation Performance: Features excellent electrical insulation, effectively preventing current leakage and short circuits in electrical problems, ensuring safety and reliability in electronic devices and electrical projects.

NB Technology Co., Ltd. custom specifications based on specific usage scenarios and characteristics of the item being stuck, including custom temperature resistance.

Clean the bonding surface: Before applying the tape, ensure the bonding surface is clean, dry, oil-free, and dust-free to improve the adhesion effect of the tape.

Bonding technique: Apply the tape smoothly onto the bonding surface, gently press the tape with fingers or tools to ensure full contact between the tape and the bonding surface.

Apply pressure: During application, apply appropriate pressure to allow the tape to better adhere to the bonding surface, enhancing the bonding effect.

Storage suggestions: Store double-sided Teflon tape in a cool, dry place away from direct sunlight and high temperatures to ensure the stability of the tape's performance.

Avoid contamination: During use, avoid contact between the tape and oil, chemicals, etc., to prevent affecting the adhesion and performance of the tape.

Cleaning method: If the tape surface gets dirty or stained, gently wipe with a clean damp cloth, let the tape surface dry before continuing to use.

Advantages

| Item description: | Teflon High-temperature Double-sided Tape |

| Brand name: | NB |

| Adhesive: | Silicone |

| Feature: | ● Good flame retardancy, easy to peel; ● Good flexibility, good adhesion, easy to use; ● Acid and alkali resistance, excellent insulation properties, strong voltage resistance; ● High temperature and cold resistance, long-term application temperature -50 ℃ to 260 ℃, short-term 350 ℃. |

| Usage: | ● Mainly used in SMT reflow soldering, eyelash hair base card;● Fixture nameplates or panels and parts adhesion, etc. |

| Substrate material: | Fiberglass cloth |

| Initial adhesion: | ≥17 |

| Thickness of substrate: | 100 microns |

| Peel force (g/25mm): | ≥800 |

| Specification: | Can be totally customized for you |

| Color: | White |

| MOQ: | About 600Kgs |

| Delivery time: | Within 15 days through peak and off season for you |

| Sample: | Free sample is always available for you to test our quality |

| Packing: | Carton packaging |

| Payment method: | T/T / L/C /Cash or negotiable |

| HS Code: | 3919909090 |

Production Process

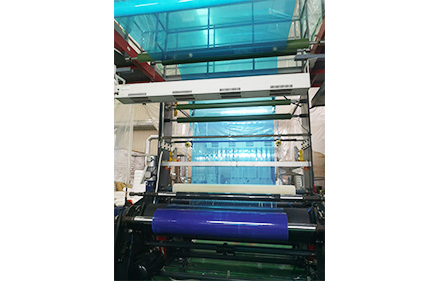

FILM BLOWING

In the film blowing process, we use advanced production equipment and imported raw materials to strictly control the protective film quality from the source.

PRINTING

In the printing process, we use environmentally friendly painting by introducing advanced production techniques and equipment, it is now possible to print four patterns and colors in one film.

COATING

We use imported glue and strictly control the quality of finished films, to achieve moderate viscosity and ensure no residue after the removal, also provide you with a good experience of use.

CUTTING

There are seven machines in our cutting workshop, each and every one of them can be adjusted to cut different lengths of protective films to meet your needs.

PACKAGING

We use standard seaworthy packaging to pack the films for you to avoid any possible damage during the transit and storage, packing of customization is also available for you.

Film Blowing

In the film blowing process, we always insist on using brand new and environmental-friendly LLDPE raw materials to ensure the stable quality from the very beginning and we absolutely say “No” to any recycled raw materials.

Film Casting

In the film casting process, our experienced team has every input data precisely set and checked to ensure the good and stable output of our final stretch wrap films. Because we always pay particular attention to every single detail during the whole proce

Film Testing

Our stretch wrap films feature strong toughness and tear resistance, and can not be penetrated easily by the nib under the intense stretch. They also feature strong tensile strength which enables you to wrap three more pallets with the same meters.

Packaging

We use standard seaworthy packaging to pack the stretch wrap films for you to avoid any possible damage during the transit and storage, you can also enjoy customized packaging from our side.

FILM BLOWING

In the film blowing process, we use advanced production equipment and imported raw materials to strictly control the protective film quality from the source.

Container Stuffing

Protective Film for Deep Drawing

Transportation of Protective Film for Deep Drawin

Packing of Protective Film for Deep Drawin

Loading of Protective Film for Deep Drawin

Navigation

+86 158 1691 5404

+86 757 8271 3937

+86 757 8271 3937

No. 10 Industry Huacongsiyue Village, Shishan Town, Nanhai District, Foshan, Guangdong Province, China