Overview

High-quality PET as a substrate, coated with high-performance acrylic adhesive, and then composite release film made of rolls of adhesive tape, strong adhesive force and durability anti-reverse elasticity, strong adhesive solid, the surface of the nano-ceramic process effectively resist stains, oil stains easy to wipe can be removed to facilitate daily care.

Can be used for marble furniture, all kinds of glass plus furniture, piano lacquer furniture, matte lacquer furniture, mahogany furniture, oak furniture and other furniture with smooth surface.

Specifications

| Item description: | Furniture Explosion-proof Film |

| Brand name: | NB |

| Prime material: | PET |

| Color: | Clear |

| Adhesion type: | Acrylic |

| Thickness: | 0.06-0.1mm |

| Peeling force: | 16-25N/25mm |

| Length: | 2-12N/25mm |

| Width: | 10-1600 Mm |

| Cutting and slitting: | As per your requirement |

| MOQ: | About 600Kgs |

| Delivery time: | Within 15 days through peak and off season for you |

| Sample: | Free sample is always available for you to test our quality |

| Packing: | These protective films are packed in cartons or pallets if LCL |

| Payment method: | T/T / L/C /Cash or negotiable |

| HS Code: | 3919909090 |

Production Process

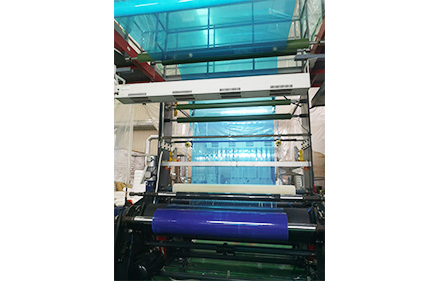

FILM BLOWING

In the film blowing process, we use advanced production equipment and imported raw materials to strictly control the protective film quality from the source.

PRINTING

In the printing process, we use environmentally friendly painting by introducing advanced production techniques and equipment, it is now possible to print four patterns and colors in one film.

COATING

We use imported glue and strictly control the quality of finished films, to achieve moderate viscosity and ensure no residue after the removal, also provide you with a good experience of use.

CUTTING

There are seven machines in our cutting workshop, each and every one of them can be adjusted to cut different lengths of protective films to meet your needs.

PACKAGING

We use standard seaworthy packaging to pack the films for you to avoid any possible damage during the transit and storage, packing of customization is also available for you.

Film Blowing

In the film blowing process, we always insist on using brand new and environmental-friendly LLDPE raw materials to ensure the stable quality from the very beginning and we absolutely say “No” to any recycled raw materials.

Film Casting

In the film casting process, our experienced team has every input data precisely set and checked to ensure the good and stable output of our final stretch wrap films. Because we always pay particular attention to every single detail during the whole proce

Film Testing

Our stretch wrap films feature strong toughness and tear resistance, and can not be penetrated easily by the nib under the intense stretch. They also feature strong tensile strength which enables you to wrap three more pallets with the same meters.

Packaging

We use standard seaworthy packaging to pack the stretch wrap films for you to avoid any possible damage during the transit and storage, you can also enjoy customized packaging from our side.

FILM BLOWING

In the film blowing process, we use advanced production equipment and imported raw materials to strictly control the protective film quality from the source.

Container Stuffing

Protective Film for Deep Drawing

Transportation of Protective Film for Deep Drawin

Packing of Protective Film for Deep Drawin

Loading of Protective Film for Deep Drawin

Navigation

+86 158 1691 5404

+86 757 8271 3937

+86 757 8271 3937

No. 10 Industry Huacongsiyue Village, Shishan Town, Nanhai District, Foshan, Guangdong Province, China